Perovskite Solar Cell Manufacturing Equipment: Definition, Process, Types, and Key Considerations

Perovskite solar cells (PSCs) represent a promising advancement in photovoltaic technology due to their high power conversion efficiency (PCE), low production costs, and versatility. Unlike traditional silicon-based solar cells, perovskite solar cells use a class of materials with the crystal structure ABX₃, where A is an organic cation, B is a metal cation, and X is a halide anion. The manufacturing of PSCs requires specialized equipment tailored to handle the unique properties and sensitivities of perovskite materials.

In this article, we will explore the definition, process, types, applications, advantages, and key considerations of perovskite solar cell manufacturing equipment.

---

●What Is Perovskite Solar Cell Manufacturing Equipment?

Perovskite solar cell manufacturing equipment refers to the machinery and tools used to fabricate perovskite solar cells. These systems are designed to handle the delicate processes involved in synthesizing, depositing, and characterizing perovskite layers while maintaining high precision and reproducibility. The equipment ensures that each step of the manufacturing process adheres to strict quality standards, enabling the production of efficient and stable perovskite solar cells.

---

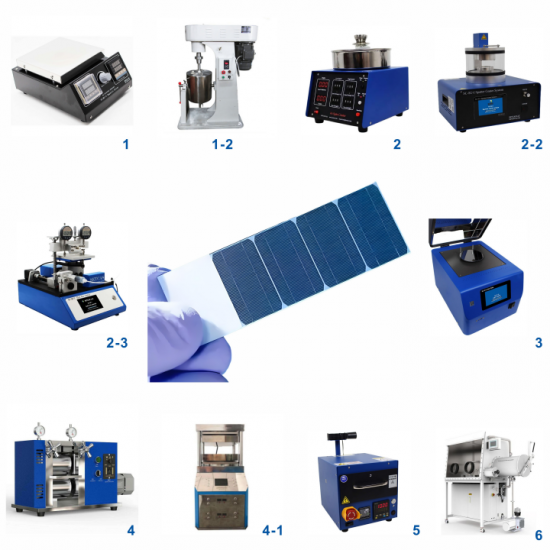

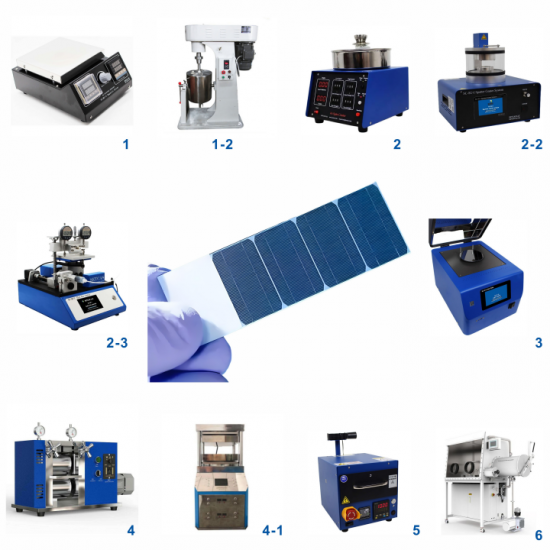

Solar Cell Research Equipment

●Perovskite Solar Cell Manufacturing Process

The fabrication of perovskite solar cells involves several critical steps:

1. Substrate Preparation

- Description: Cleaning and functionalizing the substrate (e.g., glass, flexible substrates) to ensure proper adhesion of subsequent layers.

- Equipment: Ultrasonic cleaners, plasma treatment systems.

2. Electrode Deposition

- Description: Depositing the bottom electrode layer (e.g., fluorine-doped tin oxide, FTO) onto the substrate.

- Equipment: Sputtering systems, thermal evaporators.

3. Hole Transport Layer (HTL) Deposition

- Description: Applying a layer that facilitates the transport of positive charges (holes).

- Equipment: Spin coaters, slot die coaters, vapor deposition systems.

4. Perovskite Layer Deposition

- Description: Depositing the active perovskite layer using solution-based or vacuum-based techniques.

- Equipment: Spin coaters, spray coaters, chemical vapor deposition (CVD) systems.

5. Electron Transport Layer (ETL) Deposition

- Description: Adding a layer that facilitates the transport of electrons.

- Equipment: Atomic layer deposition (ALD) systems, sputtering systems.

6. Top Electrode Deposition

- Description: Applying the top electrode layer (e.g., gold, silver) to complete the cell structure.

- Equipment: Thermal evaporators, sputtering systems.

7. Encapsulation

- Description: Protecting the perovskite layer from moisture, oxygen, and other environmental factors.

- Equipment: Laminating machines, vacuum sealing systems.

8. Testing and Characterization

- Description: Evaluating the performance and stability of the fabricated cells.

- Equipment: Solar simulators, quantum efficiency analyzers, lifetime testers.

---

●Types of Perovskite Solar Cell Manufacturing Equipment

1. Deposition Systems

- Spin Coaters: Used for depositing thin films via solution processing.

- Spray Coaters: Ideal for large-area deposition of perovskite precursors.

- Chemical Vapor Deposition (CVD): Suitable for uniform deposition of perovskite layers under controlled conditions.

- Atomic Layer Deposition (ALD): Used for precise deposition of electron transport layers.

2. Annealing and Thermal Treatment Systems

- Oven Annealers: Used for crystallizing perovskite films at elevated temperatures.

- Rapid Thermal Processors (RTP): Enable fast and uniform heating for improved film quality.

3. Encapsulation Equipment

- Laminating Machines: Seal the perovskite layer between barrier films to enhance stability.

- Vacuum Sealing Systems: Ensure airtight seals to prevent degradation.

4. Characterization Instruments

- Solar Simulators: Measure current-voltage (I-V) characteristics under standardized light conditions.

- Quantum Efficiency Analyzers: Assess the spectral response of the cells.

- Time-Resolved Photoluminescence (TRPL) Systems: Study carrier dynamics in perovskite materials.

- Scanning Electron Microscopes (SEM): Examine surface morphology and microstructure.

5. Environmental Testing Equipment

- Humidity Chambers: Evaluate resistance to moisture exposure.

- Thermal Cycling Chambers: Test durability under varying temperature conditions.

- UV Exposure Systems: Simulate long-term UV exposure to assess degradation.

---

●Applications of Perovskite Solar Cell Manufacturing Equipment

1. Research and Development:

- Fabricating prototype cells for material optimization and device testing.

2. Industrial Production:

- Scaling up perovskite solar cell manufacturing for commercial applications.

3. Next-Generation Technologies:

- Developing tandem solar cells that combine perovskites with silicon or other materials for higher efficiency.

4. Flexible and Lightweight Devices:

- Producing perovskite solar cells on flexible substrates for portable and wearable applications.

5. Building-Integrated Photovoltaics (BIPV):

- Creating transparent or semi-transparent perovskite solar cells for windows and facades.

---

●Advantages of Perovskite Solar Cell Manufacturing Equipment

1. High Precision:

- Enables accurate control over layer thickness and composition.

2. Versatility:

- Suitable for a wide range of perovskite compositions and device architectures.

3. Scalability:

- Can be adapted for both small-scale prototyping and large-scale production.

4. Cost-Effectiveness:

- Solution-based processing reduces material waste and energy consumption.

5. Customizability:

- Allows for the development of specialized devices tailored to specific applications.

---

●Challenges in Perovskite Solar Cell Manufacturing

1. Stability Issues:

- Perovskite materials are sensitive to moisture, oxygen, and heat, requiring robust encapsulation.

2. Uniformity:

- Achieving consistent film quality across large areas can be challenging.

3. Toxicity:

- Some perovskite precursors (e.g., lead-based compounds) pose environmental and health risks.

4. Complexity:

- The multi-step fabrication process requires careful coordination of different equipment.

5. Scalability:

- Transferring lab-scale techniques to industrial production remains a significant hurdle.

---

●Key Considerations When Selecting Perovskite Solar Cell Manufacturing Equipment

1. Application Requirements:

- Choose equipment based on the specific type of perovskite solar cell being developed (e.g., rigid, flexible, tandem).

2. Measurement Accuracy:

- Ensure the equipment provides the precision needed for your experiments.

3. Automation Level:

- Decide whether you need manual, semi-automated, or fully automated systems.

4. Safety Features:

- Verify that the equipment includes safeguards against hazards like chemical exposure or vacuum leaks.

5. Budget:

- Balance cost with performance and durability when selecting equipment.

6. Support and Service:

- Ensure the manufacturer offers reliable technical support and after-sales service.

---

●Future Trends in Perovskite Solar Cell Manufacturing Technology

1. Lead-Free Perovskites:

- Development of environmentally friendly perovskite materials without toxic elements.

2. Tandem Solar Cells:

- Combining perovskites with silicon or other materials to achieve record-breaking efficiencies.

3. Large-Area Processing:

- Scaling up production techniques for commercial deployment.

4. Advanced Encapsulation:

- Innovating new methods to enhance the long-term stability of perovskite solar cells.

5. Integration of AI and Machine Learning:

- Using AI-driven algorithms for process optimization and predictive modeling.

---

●Conclusion

Perovskite solar cell manufacturing equipment plays a crucial role in advancing photovoltaic technology by enabling the production of high-efficiency, low-cost solar cells. By understanding the different types of equipment, their functions, and key considerations, manufacturers and researchers can optimize their processes and accelerate the commercialization of perovskite solar cells.

What advancements in perovskite solar cell manufacturing excite you most? Share your thoughts below! Together, let’s explore how these innovations are shaping the future of renewable energy.

+86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588