Pouch Cell Assembly Plant: A Comprehensive Overview

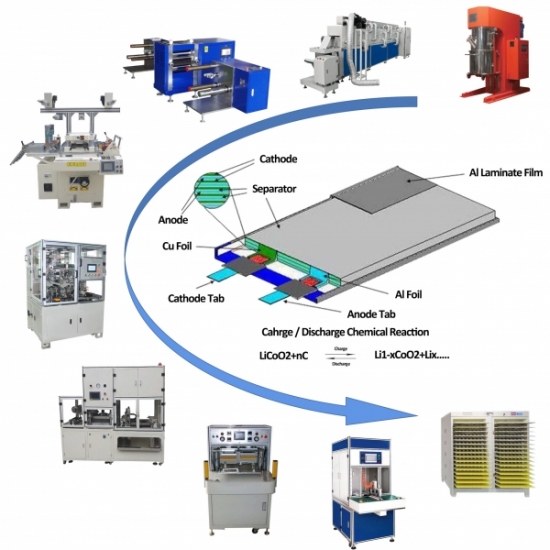

A pouch cell assembly plant is a dedicated facility designed for the manufacturing of pouch cells, a type of lithium-ion battery known for its lightweight, flexible design and high energy density. Pouch cells are widely used in various applications, including electric vehicles (EVs), consumer electronics, and energy storage systems.

● Key Components of a Pouch Cell Production Line

1. Material Preparation Area

- Electrode Materials: Active materials for the anode (usually graphite) and cathode (lithium compounds) are mixed with binders and conductive additives.

- Separator Production: Separator materials, typically made from polyethylene or polypropylene, are prepared to prevent short circuits between electrodes.

2. Electrode Fabrication

- Coating Machines: The electrode slurry is coated onto metal foils (copper for anodes and aluminum for cathodes) to achieve the desired thickness.

- Drying Ovens: Coated electrodes are dried to remove solvents and ensure optimal performance.

- Calendering Machines: Dried electrodes are compressed to improve density and enhance electrical conductivity.

3. Cutting and Shaping

- The dried electrodes are cut to precise dimensions suitable for the pouch cell design, ensuring accurate layering during assembly.

4. Cell Assembly Line

- Layer Stacking or Winding: The anode, separator, and cathode are assembled in a specific order, either stacked or wound, depending on the design.

- Electrolyte Filling: The electrolyte is injected into the assembly, saturating the electrodes and separator to facilitate ion transport.

- Pouch Sealing: The assembly is sealed in a flexible pouch, typically using heat sealing or ultrasonic welding to ensure containment and prevent leakage.

5. Formation and Aging

- Formation Cycling: The pouch cells undergo initial charge and discharge cycles to activate the electrochemical materials and stabilize performance.

- Aging: Cells are aged in controlled environments to ensure consistent long-term performance.

6. Testing and Quality Control

- Performance Testing: Each pouch cell is tested for capacity, internal resistance, voltage, and cycle life to ensure they meet specifications.

- Safety Testing: Rigorous tests for thermal stability, overcharging, and short-circuit resistance are conducted to ensure compliance with safety standards.

7. Packaging and Shipping

- Approved pouch cells are packaged for shipment to customers or for integration into battery packs.

● Advantages of Pouch Cells

1. Lightweight and Compact: Pouch cells are thinner and lighter than traditional cylindrical or prismatic cells, making them ideal for space-constrained applications.

2. High Energy Density: The flexible design allows for more active material, enhancing the overall energy density of the battery.

3. Thermal Management: The flat design facilitates effective heat dissipation, improving safety and performance during operation.

4. Customization: Pouch cells can be produced in various shapes and sizes, allowing for tailored solutions for specific applications.

● Applications of Pouch Cells

- Electric Vehicles (EVs): Widely used in battery packs for EVs due to their energy density and lightweight properties.

- Consumer Electronics: Found in smartphones, laptops, tablets, and wearable devices where space and weight are critical.

- Energy Storage Systems: Employed in grid storage solutions, solar energy systems, and backup power applications.

● Considerations for Pouch Cell Assembly

1. Environmental Control: The assembly area must maintain strict humidity and temperature controls to prevent contamination and ensure consistent quality.

2. Material Compatibility: The selection of active materials and electrolytes must be compatible to ensure optimal performance and safety.

3. Automation: High levels of automation can enhance efficiency and reduce labor costs, but require skilled personnel for operation and maintenance.

● Conclusion

A Pouch Cell fabrication Plant is crucial for producing high-performance lithium-ion batteries that meet the growing demand in various industries. With advancements in manufacturing technologies and an increasing focus on sustainability, pouch cells are expected to play a significant role in the future of energy storage solutions. As the industry evolves, pouch cell assembly plants will continue to adapt, incorporating new materials and processes to enhance efficiency and performance.

+86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588